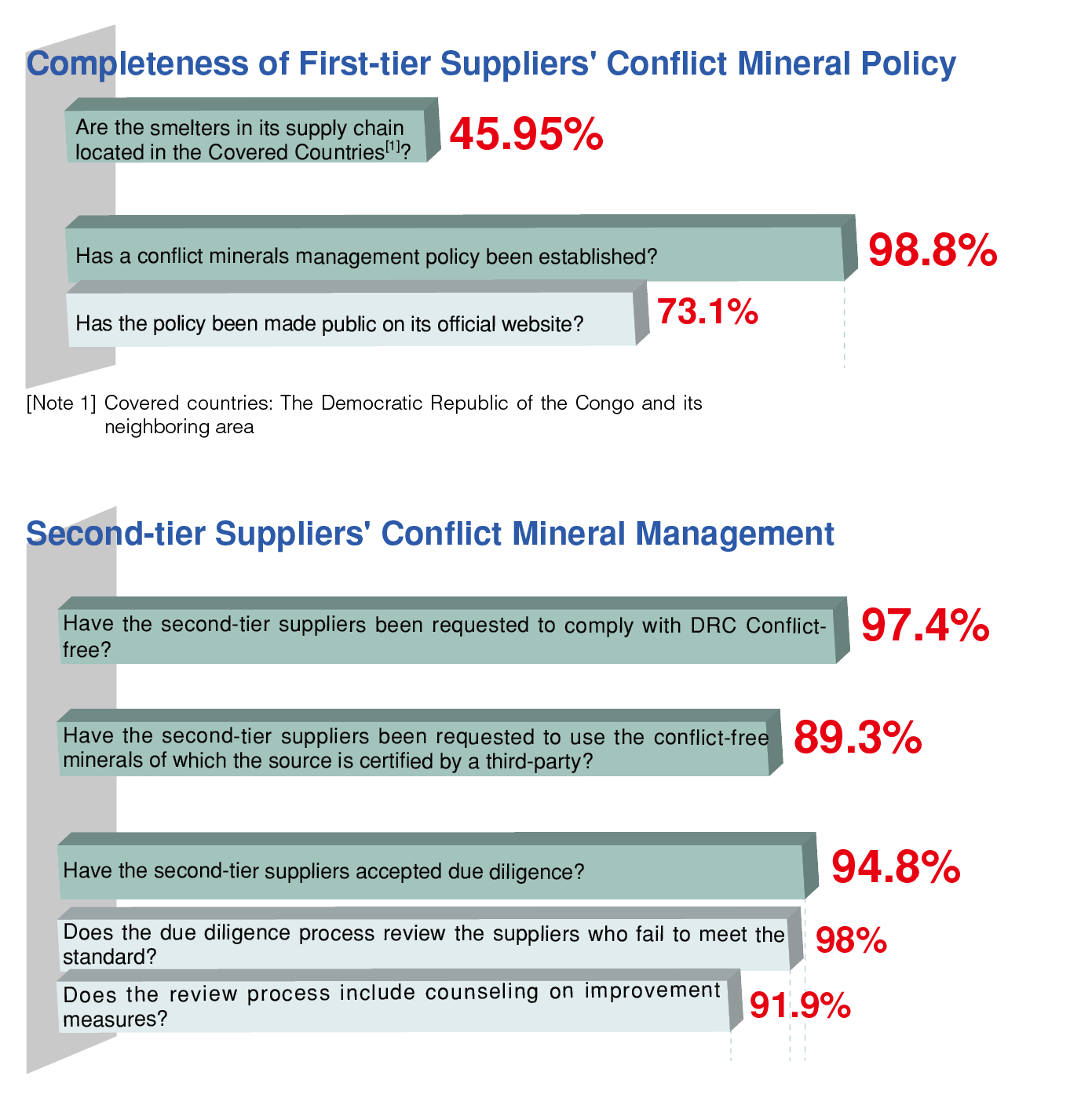

The increasing level of specialization in the industry supply chain has led to an even closer integration between the upstream and downstream parts of IT manufacturing. Suppliers are important partners of GIGABYTE, and we pursue the sustainable management of the company and growth with the suppliers through close collaboration. GIGABYTE has also adopted a 4-step approach to the sustainable supply chain. In addition to evaluating suppliers on quality, punctuality, price and service, we also use supplier audits, promotion and training to push for improvements in their sustainable supply chain. Environmental protection, respect for human rights, and improvements to workplace safety and health are used to realize the sustainable supply chain management goals of Green Action Plan 2.0 and to grow with the value chain as a whole.

Principle of Sustainable Supply Chain Management

GIGABYTE supply chain management is based on sustainable procurement. That is, we take into account all the economic, social and environmental impacts resulted from the procurement process by business. The process contains the purchased services and goods and other related operation along the supply chain. As a result, with the principle of being friendly to society and environment, we not only ensure suppliers to offer reasonable procurement prices, product quality, delivery time and services, but also consider fair trade, product responsibility, environmental protection and labor and occupational safety as key items of management. We communicate GIGABYTE’s requirements on sustainable supply chain management with our suppliers at supplier conferences as well as through required documents.

GIGABYTE develops “Guidelines of Sustainable Procurement“ in order to enable all suppliers and stakeholders to clearly understand GIGABYTE’s principles of sustainable procurement as well as to look forward to building new partnerships. All procurement activities will follow the guideline. Through the process of fulfilling cooperate social responsibility, we hope to become a reliable brand and work together with our suppliers and partners to protect the environment.

Step 1: Risk Assessment

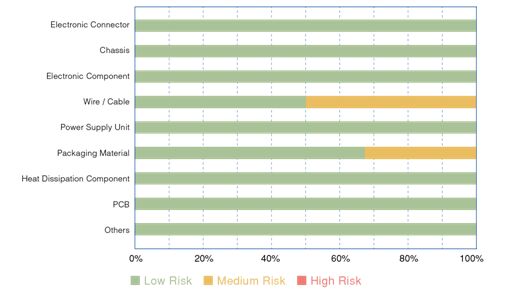

During the screening and rating of new and old suppliers, a risk assessment mechanism is applied at every stage of the process and suppliers scored on their performance. For suppliers who fail to achieve a passing score, a meeting is convened between procurement and the supplier QA executives for supplier mentoring. A deadline is also set for corrective action.

During the screening and rating of new and old suppliers, a risk assessment mechanism is applied at every stage of the process and suppliers scored on their performance. For suppliers who fail to achieve a passing score, a meeting is convened between procurement and the supplier QA executives for supplier mentoring. A deadline is also set for corrective action.

- Supplier Audit: Basic certification (environmental management system, green certification, etc.), financial audit, auditing of personnel, machinery, materials and equipment, productivity audit and up/downstream supplier audit.

- Supplier Selection: The most suitable GIGABYTE supplier is chosen from the list of qualified suppliers.

- Supplier Interaction: Guarantees on production capacity, quality and environmental friendliness are signed every year to define the rights and obligations of both parties.

- Supplier Evaluation: Regular suppliers are evaluated on a quarterly and annual basis on their quality, flexibility, pricing and service.

- Supplier Replacement: A review is conducted after supplier evaluations and inadequate suppliers replaced.

Step 2: Supplier Audit and Mentoring

The supplier audit process focuses on scoring supplier performance in three aspects: Quality System audit, RoHS audit and CSR self-assessment. Each audit category is broken down into further sub-items for scoring. Random supplier inspections on product responsibility, environmental protection, occupational safety and health, and sustainable development are also conducted as well. Counseling was provided to at-risk suppliers and deadlines imposed for corrective action to improve product quality, reduce corporate risk, realize joint growth with the supplier, and fulfill the goal of mutual success. GIGABYTE will terminate its relationship with any supplier found to have negative impacts on local society by violating local social or labor-related laws and regulations.

In 2019, RoHS and product quality audits were conducted at 36 suppliers with a majority of issues among moderate and high-risk vendors found to be quality-related. GIGABYTE provided these vendors with counseling before reviewing their eligibility for the qualified supplier list. As for the CSR aspect, in 2019, 47 suppliers were assessed in accordance with the Responsible Business Alliance (RBA) Code of Conduct. All of the suppliers were assessed as excellent (scoring over 85) and the average score was 92.33. When comparing the audit outcomes between 2017 and 2019, there was not only an increase in the number of audited vendors but also improvements in vendor ratings every year. GIGABYTE’s long-term advocacy and mentoring have helped our supply chain partners join in the fulfillment of corporate social responsibilities.

The supplier audit process focuses on scoring supplier performance in three aspects: Quality System audit, RoHS audit and CSR self-assessment. Each audit category is broken down into further sub-items for scoring. Random supplier inspections on product responsibility, environmental protection, occupational safety and health, and sustainable development are also conducted as well. Counseling was provided to at-risk suppliers and deadlines imposed for corrective action to improve product quality, reduce corporate risk, realize joint growth with the supplier, and fulfill the goal of mutual success. GIGABYTE will terminate its relationship with any supplier found to have negative impacts on local society by violating local social or labor-related laws and regulations.

In 2019, RoHS and product quality audits were conducted at 36 suppliers with a majority of issues among moderate and high-risk vendors found to be quality-related. GIGABYTE provided these vendors with counseling before reviewing their eligibility for the qualified supplier list. As for the CSR aspect, in 2019, 47 suppliers were assessed in accordance with the Responsible Business Alliance (RBA) Code of Conduct. All of the suppliers were assessed as excellent (scoring over 85) and the average score was 92.33. When comparing the audit outcomes between 2017 and 2019, there was not only an increase in the number of audited vendors but also improvements in vendor ratings every year. GIGABYTE’s long-term advocacy and mentoring have helped our supply chain partners join in the fulfillment of corporate social responsibilities.

2019 Audit Result of Suppliers’ Quality and RoHS

2019 Audit Result of Suppliers’ CSR Performance

Step 3: Supplier Evaluation

GIGABYTE offers the Partner Excellence Award, Best Partner Award and Supplier Sustainability Award to encourage suppliers to actively embrace our expectations on service/product quality control and sustainable supply chain management. We also publicly thank and recognize our supplier partners for their long-term support and contributions during the annual supplier conference.

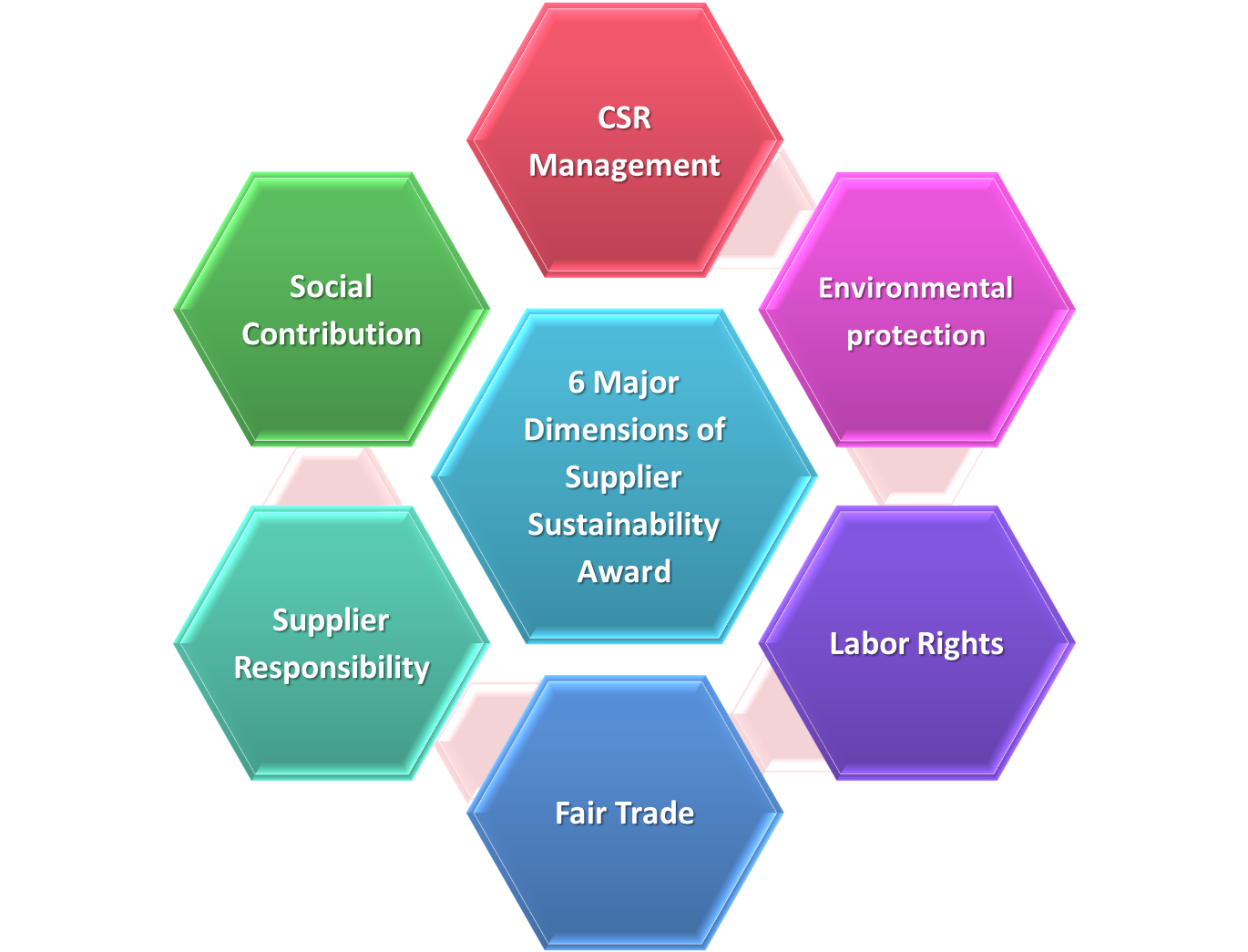

Started in 2012, the Sustainable Supplier Award has been held for 8 years. GIGABYTE designs an annual CSR evaluation tool for suppliers based on the request of supplier chain management and the promotion of sustainability project. Moreover, as social attention on CSR becomes higher and higher, we modify the contents of the evaluation tool in 2017 in order to enhance the discrimination of the evaluation tool. The performance related to responding to UN Sustainable Development Goals, greenhouse gas, water resources and waste management, and labor rights management were added to the evaluation.

GIGABYTE offers the Partner Excellence Award, Best Partner Award and Supplier Sustainability Award to encourage suppliers to actively embrace our expectations on service/product quality control and sustainable supply chain management. We also publicly thank and recognize our supplier partners for their long-term support and contributions during the annual supplier conference.

Started in 2012, the Sustainable Supplier Award has been held for 8 years. GIGABYTE designs an annual CSR evaluation tool for suppliers based on the request of supplier chain management and the promotion of sustainability project. Moreover, as social attention on CSR becomes higher and higher, we modify the contents of the evaluation tool in 2017 in order to enhance the discrimination of the evaluation tool. The performance related to responding to UN Sustainable Development Goals, greenhouse gas, water resources and waste management, and labor rights management were added to the evaluation.

Step 4: Sustainable supply Chain Partnership

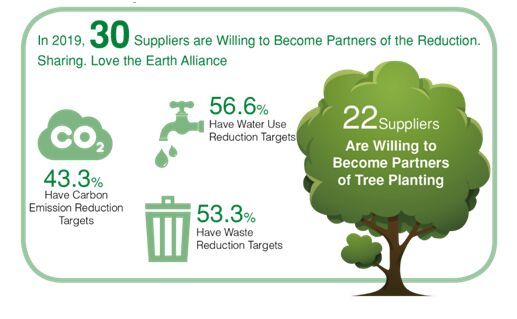

To boost tangible contributions to environmental protection from our value chain, the “Sustainable Supply Chain Partnership Initiative” was launched in 2015 with key suppliers invited to take part. In 2018, we hosted a Supplier Sustainability Conference to jointly learn and share experiences on topics like sustainable operations and the circular economy with suppliers. We look forward to welcoming more supply chain partners to join our “Reduction. Sharing. Love the Earth Alliance”, “333 Reduction Plan” and “Make Earth Green Again” project.

Suppliers’ responses to the 333 Reduction Plan and the Make Earth Green Again project

End-of-year Suppler Party – Communicating Management Goals and Building Consensus

To make the suppliers understand GIGABYTE’s requirement for quality, environmental issues and sustainable management of the supply chain, we hold supplier conferences to promote relative issues.

|

2016 - Martial Art General Assembly The event spread GIGABYTE’s four Sustainability Principles and major environmental management objectives in the future to show our high emphasis on sustainability-related issues. • Four Sustainability Principles: Civic Duty, Empathy, Vision and Perseverance • Objectives of environmental management among suppliers:Full control of the use of Phthalates |

|

|

2017 - Jungle Game The event combined VR, drone and online interaction game with the guest to let the suppliers feel our ambition of innovation and ground-breaking. Our philosophy and conducts of carbon, waste and water reduction and plant for the planet are the main topic of the whole adventure event. We hope to cooperate and respond with other partners together, and with the principle of sustainability, innovation and quality, we can create the visions of the sustainable development for the value chain, marching toward the future of the economy, society and environment thriving together. |

|

|

2018 – Secret Gathering at Ace City A secret invitation from Ace City invited the leaders of all countries in the world of fairy tales to come together to help solve the issues facing Ace City. At the meeting, each hero could collect three magical treasures: the Sustainability Rose, the Superior Quality Candle, the Collaboration and Innovation Scepter, with which they could help solve Ace City’s issues with sustainable development, environmental conservation, and social responsibility. |

|

|

2019 - Reduction, Sharing, Love the Earth: G20 Sustainability Summit GIGABYTE invited our supplier partners to attend the G20 Sustainability Summit where formal minimalism rather than ostentation was the order of the day. Attendees were also asked to support the GIGABYTE Reduction, Sharing, Love the Earth Alliance. The pre-event games, gifts, and performances were all closely integrated with social engagement and sustainable development. The colored rings representing SDGs set into the trophies made from recycled motherboards represented GIGABYTE’s determination to lead our partners in embracing a circular economy and sustainable future! |

Establishment of Supplier Management System

GIGABYTE requires all first-tier suppliers to implement ISO14001 Environmental Management Systems and ISO 45001:2018 Occupational Health and Safety Management Systems (Original OHSAS 18001) and to cooperate with on-site inspection.

GIGABYTE requires all first-tier suppliers to implement ISO14001 Environmental Management Systems and ISO 45001:2018 Occupational Health and Safety Management Systems (Original OHSAS 18001) and to cooperate with on-site inspection.

Restrictions on Use of Hazardous Substances

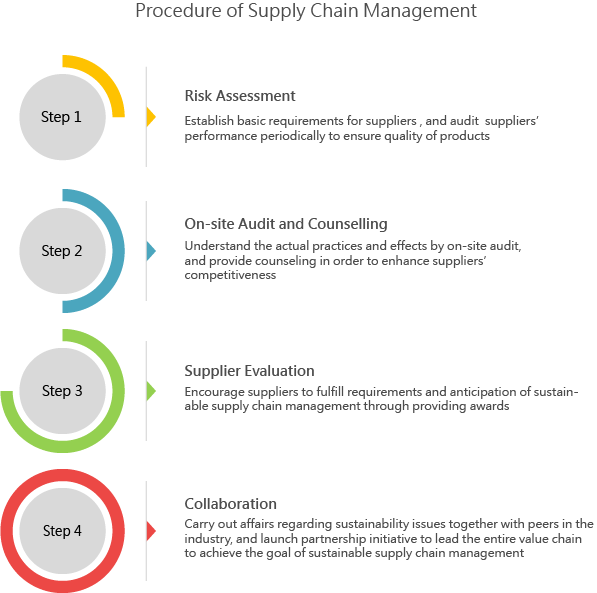

GIGABYTE became the first system brand vendor in the world to pass IECQ QC 080000 certification in 2005. Lead-free production processes were adopted for our products and a green material management system introduced to establish a green supply chain. Green Supply Chain Management (GSCM) is used to integrate component suppliers and link to the relevant regulatory review and approval processes. Through effective communication, tracking and management, components that contain restricted chemical substances are eliminated from the supply chain. All suppliers can use the system platform to check the latest version of HCSR issued by GIGABYTE Group as well as the relevant green product specifications.

Product suppliers are required to conform to the GIGABYTE Technology Group Guideline for the Management of Harmful Chemical Substances Requirements (HCSR), RoHS, WEEE and other regional pollution prevention or waste disposal-related environmental regulations. For environmental laws or substance management regulations specified by GIGABYTE such as the Substance of Very High Concern (SVHC) defined by the EU REACH legislation or Level B and Level C substances defined in the HCSR, suppliers should cooperate with inspections and voluntarily report the results. Suppliers must also sign the Certificate of Non-use of the Controlled Substances as well as a declaration of conformity on SVHC in EU REACH legislation.

In response to the additional control on PAE materials by RoHS 2.0 and the amendment of REACH, we revised the HCSR in 2017 to adjust the control level (from Level B to Level A) of the 4 PAE materials (DEHP, BBP, DBP, DIBP) and add 2 prohibited substances of DBB and PFOSF. To ensure that all of the products meet the RoHS 2.0 requirement by 2019, we have promoted and activated the control requirements at the year-end event of the suppliers since 2016. An overall inspection and spot check of the suppliers was conducted in 2017 and the suppliers of high risk must provide a test report from the lab of a third party. Follow-up actions are taken afterward to ensure that all the suppliers meet the HCSR.

GIGABYTE became the first system brand vendor in the world to pass IECQ QC 080000 certification in 2005. Lead-free production processes were adopted for our products and a green material management system introduced to establish a green supply chain. Green Supply Chain Management (GSCM) is used to integrate component suppliers and link to the relevant regulatory review and approval processes. Through effective communication, tracking and management, components that contain restricted chemical substances are eliminated from the supply chain. All suppliers can use the system platform to check the latest version of HCSR issued by GIGABYTE Group as well as the relevant green product specifications.

Product suppliers are required to conform to the GIGABYTE Technology Group Guideline for the Management of Harmful Chemical Substances Requirements (HCSR), RoHS, WEEE and other regional pollution prevention or waste disposal-related environmental regulations. For environmental laws or substance management regulations specified by GIGABYTE such as the Substance of Very High Concern (SVHC) defined by the EU REACH legislation or Level B and Level C substances defined in the HCSR, suppliers should cooperate with inspections and voluntarily report the results. Suppliers must also sign the Certificate of Non-use of the Controlled Substances as well as a declaration of conformity on SVHC in EU REACH legislation.

In response to the additional control on PAE materials by RoHS 2.0 and the amendment of REACH, we revised the HCSR in 2017 to adjust the control level (from Level B to Level A) of the 4 PAE materials (DEHP, BBP, DBP, DIBP) and add 2 prohibited substances of DBB and PFOSF. To ensure that all of the products meet the RoHS 2.0 requirement by 2019, we have promoted and activated the control requirements at the year-end event of the suppliers since 2016. An overall inspection and spot check of the suppliers was conducted in 2017 and the suppliers of high risk must provide a test report from the lab of a third party. Follow-up actions are taken afterward to ensure that all the suppliers meet the HCSR.

Set of Zero-tolerance Policies in Compliance with RBA Code of Conduct

GIGABYTE commits to complying with local laws under high moral standards and also obeying regulations of industrial responsibility. Although we are not a formal member of the Responsible Business Alliance (RBA, originally known as EICC), we voluntarily support “Code of Conduct – Responsible Business Alliance, RBA”.

GIGABYTE commits to complying with local laws under high moral standards and also obeying regulations of industrial responsibility. Although we are not a formal member of the Responsible Business Alliance (RBA, originally known as EICC), we voluntarily support “Code of Conduct – Responsible Business Alliance, RBA”.

• Diversity and Nondiscrimination

• Harassment Prohibition

• Workplace Safety

• Prevention of Human Trafficking, Forced Labor and Child Labor

• Working Hours and Minimum Wage Standards

• Freedom of Association/Collective Bargaining

• Privacy and Freedom of Expression

In order to effectively carry out supply chain management, GIGABYTE amended the documentation to re-establish criteria for supplier evaluation and requirements for signing contract/commitment in 2017. Four zero-tolerance policies were also established. GIGABYTE has a zero tolerance for the use of child labor, forced labor, discharge of untreated toxic or harmful matters or materials, and any behavior that may cause direct injury to employees. If any violation is identified, the improvement shall be made within a specified time frame. If the supplier designated by a customer fails to improve as scheduled, GIGABYTE would notify the customer. If the supplier that is not designated by any customer fails to meet the improvement standards, we would reduce orders, cease the business, or cancel the qualification of the supplier in order to avoid risks of supply chain and losses to our customers. For more information about the RBA, please visit the RBA website at http://www.responsiblebusiness.org/ .

• Product Responsibility and Environmental Stewardship

In addition to ethical requirements, to fully understand the impact of products on the environment and society, GIGABYTE has launched a product environmental responsibility disclosure project since 2016. For more details, please refer to Extended Product Responsibility.

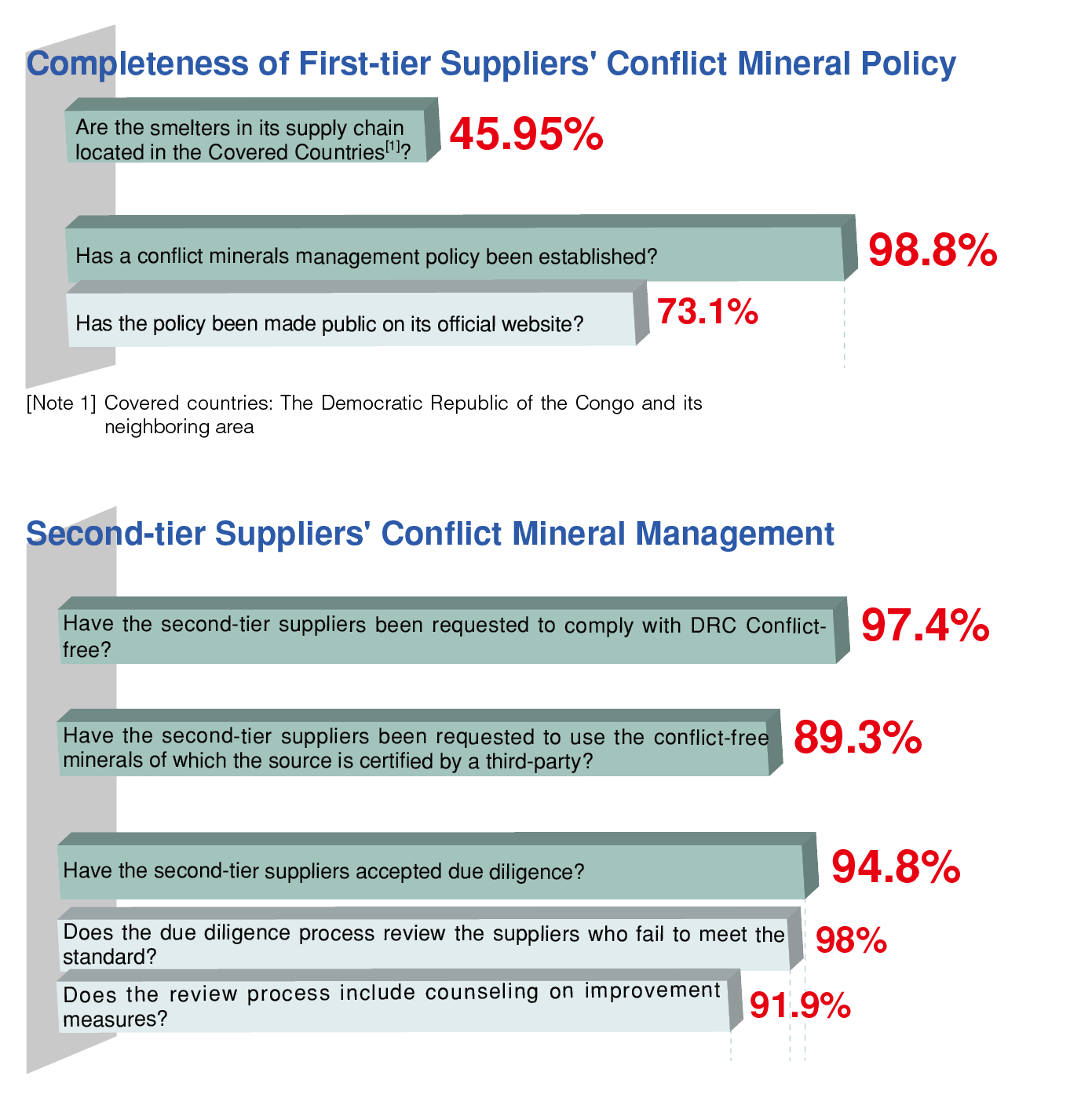

Non-use of Conflict Minerals

Conflict minerals refer to minerals from war zones and illegal mining operations involving human rights abuse and harsh working conditions. For example, Tantalum, Tin, Tungsten and Gold from mines in the Democratic Republic of the Congo and neighboring countries controlled by armed militia are used to fund further armed conflicts. These metals are extensively used in the technology and manufacturing industries, and thus would bring a serious risk in sustainable supply chain management. GIGABYTE has used our official website and supply contracts to communicate with our suppliers that we oppose and do not use conflict minerals. We also conduct non-use inspections to reduce the impact of “conflict minerals” and ensure that suppliers take the same stance as GIGABYTE on the procurement of conflict minerals.

We take self-management measures in the hope to complete the conflict mineral management by signing letters of undertaking, investigating conflict minerals, and analyzing relevant issues.

Conflict minerals refer to minerals from war zones and illegal mining operations involving human rights abuse and harsh working conditions. For example, Tantalum, Tin, Tungsten and Gold from mines in the Democratic Republic of the Congo and neighboring countries controlled by armed militia are used to fund further armed conflicts. These metals are extensively used in the technology and manufacturing industries, and thus would bring a serious risk in sustainable supply chain management. GIGABYTE has used our official website and supply contracts to communicate with our suppliers that we oppose and do not use conflict minerals. We also conduct non-use inspections to reduce the impact of “conflict minerals” and ensure that suppliers take the same stance as GIGABYTE on the procurement of conflict minerals.

We take self-management measures in the hope to complete the conflict mineral management by signing letters of undertaking, investigating conflict minerals, and analyzing relevant issues.

• Promoting social responsibility and code of conduct among suppliers; confirming. Subscription of the letter of undertaking for social responsibility.

• Establishing internal systematic and documented management systems.

• Establishing an annual supplier investigation system.

• Analyzing and retaining conflict mineral investigation data.

With reference to the list of qualified smelters announced by the Conflict-free Sourcing Initiative (CFSI; renamed to Responsible Minerals Initiative or RMI in 2017), we prioritized a conflict mineral investigation for the suppliers with high potential risks in 2016. Afterward, we kept expanding the scope of investigation over the years in order to implement the requirements of our anti-conflict-mineral policy. The number of suppliers involved in the investigation was 303 in 2017 and increased to 424 in 2019. Moreover, in response to the extension of the dedicated focus area by RMI, we conducted a cobalt survey on a total of 286 suppliers in 2019.

• Establishing internal systematic and documented management systems.

• Establishing an annual supplier investigation system.

• Analyzing and retaining conflict mineral investigation data.

With reference to the list of qualified smelters announced by the Conflict-free Sourcing Initiative (CFSI; renamed to Responsible Minerals Initiative or RMI in 2017), we prioritized a conflict mineral investigation for the suppliers with high potential risks in 2016. Afterward, we kept expanding the scope of investigation over the years in order to implement the requirements of our anti-conflict-mineral policy. The number of suppliers involved in the investigation was 303 in 2017 and increased to 424 in 2019. Moreover, in response to the extension of the dedicated focus area by RMI, we conducted a cobalt survey on a total of 286 suppliers in 2019.

The Result of Conflict Minerals Investigation of Supply Chain in 2019