|

|

|

|

|

|

Built to Last

More Durable for Longer Lifetime |

|

|

|

|

|

| |

|

|

|

More Durable for Longer Life Time |

|

| |

| Advantages of 50,000 Hour Japanese Solid Capacitors |

|

|

|

| |

GIGABYTE Ultra Durable™ motherboards are equipped with solid capacitors developed by leading Japanese manufacturers. With an average lifespan of 50,000 hours, these solid capacitors provide the stability, reliability and longevity essential to meet the power needs of high-end processors and other components running today's most demanding applications and games. |

|

| |

|

|

| |

|

|

1 year = 24 hr. x 365 days = 8,760 hr.

5 years = 8,760 hr. x 5 = 43,800 hr.

|

| |

* 50,000 hr. of work time is calculated at 85°C temperature. |

|

|

|

| |

|

TOP TOP |

| |

|

|

| |

| |

|

|

| |

|

| |

|

| |

|

| |

|

Element |

| |

|

| |

|

PEDT |

| |

|

| |

|

|

| Terminal |

|

Terminal

Rubber |

| |

| |

|

|

|

| |

What are Solid Capacitors? |

|

| |

Solid capacitors and electrolytic capacitors both store electricity and discharge it when needed. The difference is that solid capacitors contain a solid organic polymer, while electrolytic capacitors use a liquid electrolyte. |

|

| |

|

|

|

Solid Capacitors |

|

| |

Separator sheet (electrolyte) impregnated with conductive polymer. Solid capacitors are composed of highly electro-conductive polymer that dramatically improve stability and reliability. |

|

| |

|

|

|

|

Aluminum Electrolyte Capacitor |

|

|

| |

Separator sheet (electrolyte) impregnated with electrolytic solution. |

| |

|

|

|

| |

|

|

| |

Solid Capacitor |

Aluminum Electrolyte Capacitor |

|

|

|

|

| |

|

TOP TOP |

| |

|

|

| |

|

|

| |

Why use Solid Capacitors? |

|

| |

Electro-conductive polymer used in solid capacitors helps to achieve the following characteristics: |

|

| |

| |

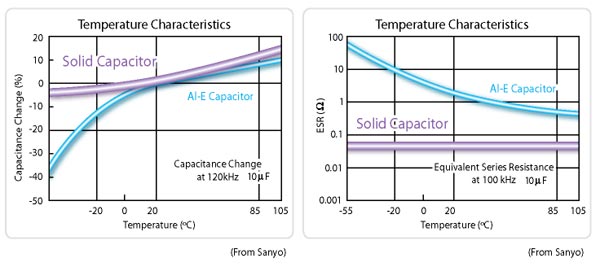

Low ESR in High Frequency Area |

| |

High Ripple Current |

| |

Longer Life |

| |

High Temperature Capability |

|

|

|

| |

|

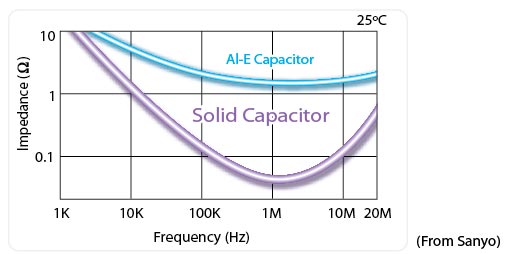

Low ESR in High Frequency Area=Cooler Motherboard |

| |

The Lower Equivalent Series Resistance (ESR) means Less power - solid capacitors are able to deliver substantially lower impedance at higher frequencies. Because there is less impedance, solid capacitors are more stable and generate less heat than electrolytic capacitors. |

| |

|

|

|

| |

|

TOP TOP |

| |

|

|

| |

|

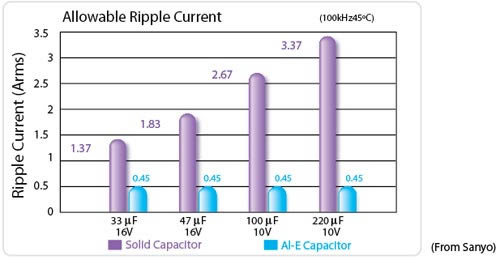

Tolerating High Ripple Current for a More Stable Motherboard |

| |

Higher Ripple Current absorbs higher power switching that plays a decisive role in motherboard power phase design. Solid capacitors have better capacity for power switching and thus, contribute significantly to better motherboard stability compared to electrolytic capacitors. |

| |

|

|

|

| |

|

|

| |

|

|

| |

|

High Temperature Capability - More Reliable Motherboard |

| |

The capacitance of solid capacitors stays stable in sharp changing temperatures - Solid capacitors deliver more stable capacitance and are less likely to be affected by temperature changes. As the chart shows, even at extreme temperatures, solid capacitors have relatively stable capacitance, especially when compared to electrolytic capacitors. |

| |

|

|

|

| |

|

TOP TOP |

| |

|

|

| |

|

Longer Life - More Durable Motherboards |

| |

In terms of lifespan, solid capacitors last longer than electrolytic capacitors, especially at lower working temperatures. As the table below shows, at 85ºC, the average lifespan for a Japanese solid capacitor is more than six times greater than electrolytic capacitors. In actual years, the Japanese solid capacitor will last approximately 5 years, while the electrolytic capacitor dies after only one years. Clearly, solid capacitors have a lifetime advantage over electrolytic capacitors. |

| |

|

| |

Temp°C |

Electrolytic Capacitors

(Working Hours) |

Japanese Solid Capacitors (Working Hours) |

95°C |

4,000 Hr. |

15,811 Hr. |

|

85°C |

8,000 Hr. |

50,000 Hr. |

|

75°C |

16,000 Hr. |

158,113 Hr. |

|

65°C |

32,000 Hr. |

500,000 Hr. |

|

|

| |

|

| |

|

No More Exploding Capacitors - More Stability for Overclocking

Swelling and leaking capacitors have bothered motherboard users for ages. This dramatically lowers a PC's performance, and may even damage the motherboard to the point where it can no longer operate. As there is no liquid component to solid capacitors, they don't leak or explode. In addition, their ability to tolerate extreme conditions and their overall robustness make them much more suited to extreme operating environments. |

|

Solid Capacitor and Electrolytic Capacitor Comparison

|

Characteristics |

Solid Capacitors |

Electrolytic Capacitors |

| Heat-Resistibility |

|

|

| Allowable Ripple Current |

|

|

| ESR in high Frequency |

|

|

| Safety |

|

|

| Environmental Protection |

|

|

|

| |

|

Well |

|

Normal |

|

Bad |

|

|

Summary of Solid Capacitor Features

Solid caps have a low ESR

A frequency characteristic of impendence shows an ideal curve

Ideal to use as de-coupling capacitor for removing such noise as ripple, spike, digital, static, audio, etc.

Able to handle large ripple current

Ideal for miniaturization, as a smoothing capacitor of switching power supply.

Able to discharge rapidly

Ideal for use as back-up capacitor in a circuit where large current is consumed at high-speed.

The ESR of Solid capacitor is not greatly affected by temperature

The Solid cap can be used for low temperature specification equipment (0ºC or less)

Solid caps enjoy a longer life

You can expect to use Solid caps for 50,000Hrs (5 years) at 85ºC

This is ideal for devices that should last for a long period. |

|

|

|

|

| |

|

|

| |

|

TOP TOP |

|

| |

| |

Quality Components make Quality Motherboards |

|

| |

|

|

| |

Using high quality components on a motherboard is the key factor for having a long lasting, stable and reliable product. This is especially the case for the power circuit design, which features the most critical components of a motherboard.

GIGABYTE has set the industry standard by using All-Solid Capacitors throughout a wide range of products in 2006. In 2007, GIGABYTE set a new standard by using Ferrite Core Chokes and Lower RDS(on) MOSFETs for its latest upcoming products.

Ferrite core chokes have higher energy efficiency compared to the commonly used iron core chokes because they are able to store energy longer and prevent rapid energy loss at high frequency. Lower RDS(on) MOSFETs have a lower resistance, which reduces power consumption and heat generation. |

|

| |

|

New Design

Ultra Durable 2 |

Old Design |

| |

Lower RDS(on)

MOSFET |

|

Standard

MOSFET |

| |

Ferrite Core

Choke |

|

Iron Core

Power Inductor |

| |

Lower ESR

Solid Capacitor |

|

Traditional

Solid Capacitor |

|

|

|

|

|

|

| |

|

|

| |

Lower RDS(on) MOSFETs |

|

| |

• Optimized gate charge to minimize switching losses.

• Lower temperature, smaller size, better thermal characteristics. |

|

| |

|

|

What is a MOSFET?

A MOSFET is a switch that allows or disallows electric current to pass through an electronic circuit. |

|

|

| |

|

|

|

|

| |

Lower RDS(on) MOSFET |

16% Lower |

| |

|

| |

|

| |

|

|

|

|

|

| |

When compared to standard MOSFETs, RDS(on) MOSFETs temperatures are 16% lower. |

|

| |

|

|

| |

| |

Lower Resistance = Lower Power Consumption = Lower Heat |

|

|

| |

|

|

| |

Heat is a by-product

of power consumption |

|

Power Consumption |

| |

|

|

|

|

| |

Power Equation: P = I 2 x R

(P: Power, I : Current, R: Resistance) |

|

|

|

| |

|

|

| |

Ferrite Core Chokes |

|

| |

• Reduced core energy loss • Lower EMI interference

• Resists rust better than standard iron core chokes |

|

| |

|

|

What is a Choke?

A choke is an inductor that stores energy and regulates current. |

|

|

| |

|

|

|

|

| |

Ferrite Core Choke |

|

25% Lower |

| |

|

| |

|

| |

|

|

|

|

|

| |

|

|

| |

How does the Ultra Durable™ 2 Power Design Work? |

|

| |

| Power |

|

|

|

|

| |

Store energy

and

regulate current

|

Store and

discharge electric current

|

|

Lower RDS(on)

MOSFET

To stop/allow

the electric current

to flow through

|

|

|

|

|

| |

Ferrite Core

Choke |

Lower ESR

Solid Capacitor |

|

Processor |

|

|

|

| |

|

|

| |

|

|

|

|

|