GIGABYTE's Quality Assurance Testing

All GIGABYTE Ultra Durable motherboards must pass rigorous tests in GIGABYTE’s R&D Laboratory. These demanding procedures have been executed for decades and improved upon year over year to ensure the highest level of quality, stability, and performance of Ultra Durable products under various critical conditions.

All GIGABYTE Ultra Durable motherboards must pass rigorous tests in GIGABYTE’s R&D Laboratory. These demanding procedures have been executed for decades and improved upon year over year to ensure the highest level of quality, stability, and performance of Ultra Durable products under various critical conditions. These testing programs ensure that GIGABYTE Ultra Durable motherboards meet our highest standards of quality as well as the most demanding usage environments that customers may have. For Example; GIGABYTE Ultra Durable Motherboards can withstand temperatures of 50°C and up to 98% humidity and lows down to -10°C as well as a +/- 7% over-voltage or under-voltage of input power. These tests simulate long durations of sea shipments as well as extreme temperatures in hot or cold regions around the world.

These testing programs ensure that GIGABYTE Ultra Durable motherboards meet our highest standards of quality as well as the most demanding usage environments that customers may have. For Example; GIGABYTE Ultra Durable Motherboards can withstand temperatures of 50°C and up to 98% humidity and lows down to -10°C as well as a +/- 7% over-voltage or under-voltage of input power. These tests simulate long durations of sea shipments as well as extreme temperatures in hot or cold regions around the world.To Maintain the best product quality, every GIGABYTE Ultra Durable Motherboard must withstand up to 3 days of stress testing, during those tests GIGABYTE went through hundreds of products ever year to make sure problem areas were found and resolved. As a result, GIGABYTE Ultra Durable motherboards hold the lowest repair rate in the market and acclaimed by worldwide customers.

Compatibility Testing

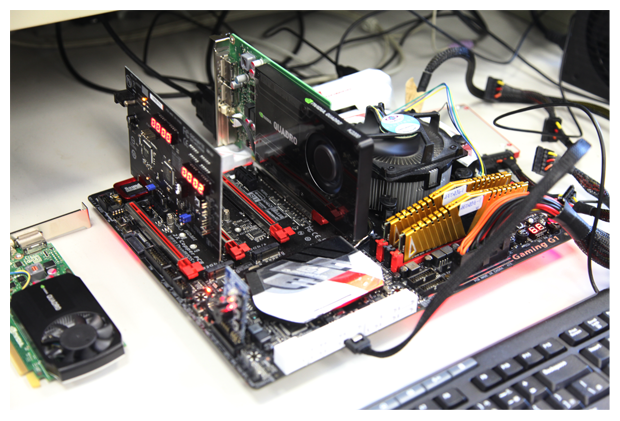

To ensure GIGABYTE Ultra Durable Motherboards are able to work with various computer components out in the market, each GIGABYTE Ultra Durable Motherboard must first pass a Compatibility Test or AVL Test (Authorization Validation List Test) in GIGABYTE’s R&D Laboratory.

To ensure GIGABYTE Ultra Durable Motherboards are able to work with various computer components out in the market, each GIGABYTE Ultra Durable Motherboard must first pass a Compatibility Test or AVL Test (Authorization Validation List Test) in GIGABYTE’s R&D Laboratory.GIGABYTE's R&D Facilities has a catalog of thousands of different computer components which include CPU, Memory, Hard Drives, SSD’s, Power Supplies, Monitors, and other parts as well.

Each GIGABYTE Ultra Durable Motherboard is tested with a variety of these different components to assure there are no compatibility issues and that each different component operates with the board properly. Once a compatibility issue is found, GIGABYTE R&D will cooperate closely with the Vendor Partners to resolve the issue. With such a vast variety of products in the market GIGABYTE’s AVL list can significantly lower compatibility issues before a product goes into mass production. If there are any issues found after production, GIGABYTE will buy the incompatible product and duplicate the issue to find and resolve the problem.

Function and Performance Test

To assure GIGABYTE Ultra Durable motherboards are functional and can reach GIGABYTE’s Internal Performance Standard, each GIGABYTE Ultra Durable motherboard must pass a Function Test as well as a Performance Test in GIGABYTE’s R&D Laboratory.

GIGABYTE R&D completes hundreds of functional checklists on each Ultra Durable Product, including, but not limited to CPU/Memory Compatibility, Expansion slot, Input/Output function, and Power Stability.

To run Performance Testing, GIGABYTE prepares several benchmark programs such as 3DMark, Specviewperf (specifically for Nvidia Quadro), and PCMark to make GIGABYTE Ultra Durable Motherboards compliant with GIGABYTE and Vendor Partner Performance Standards.

GIGABYTE R&D completes hundreds of functional checklists on each Ultra Durable Product, including, but not limited to CPU/Memory Compatibility, Expansion slot, Input/Output function, and Power Stability.

To run Performance Testing, GIGABYTE prepares several benchmark programs such as 3DMark, Specviewperf (specifically for Nvidia Quadro), and PCMark to make GIGABYTE Ultra Durable Motherboards compliant with GIGABYTE and Vendor Partner Performance Standards.

Reliability Test

To ensure GIGABYTE Ultra Durable Motherboards continue to perform their best under full load, each GIGABYTE Ultra Durable Motherboard must pass a Rigorous Reliability Test in GIGABYTE’s R&D Laboratory.

Reliability testing is performed in a series of hardware and software test procedures, including 3D Burn-in programs which stress the motherboard and graphics card. The test continuously switches the system On/Off hundreds of times, repeatedly rebooting and resuming from S3 standby mode. These series of test programs are basic quality assurance standards of GIGABYTE Ultra Durable Motherboards, furthermore GIGABYTE runs these tests under various harsh environmental conditions.

To pass these tests, GIGABYTE must use expensive and durable components with refined design layouts that are able to sustain the demanding workload under different circumstances.

Reliability testing is performed in a series of hardware and software test procedures, including 3D Burn-in programs which stress the motherboard and graphics card. The test continuously switches the system On/Off hundreds of times, repeatedly rebooting and resuming from S3 standby mode. These series of test programs are basic quality assurance standards of GIGABYTE Ultra Durable Motherboards, furthermore GIGABYTE runs these tests under various harsh environmental conditions.

To pass these tests, GIGABYTE must use expensive and durable components with refined design layouts that are able to sustain the demanding workload under different circumstances.

Stability Test

GIGABYTE built a room sized burn-in chamber with a patented power supply installation kit, where dozens of Ultra Durable Motherboards can be tested simultaneously. The Burn-in Chamber is set to 50°C to simulate the high temperature environments. Each GIGABYTE Ultra Durable motherboard model must pass all Stability Test loops, totaling 32 hours of non-stop burn-in, reboot, On/Off and resume testing.

GIGABYTE built a room sized burn-in chamber with a patented power supply installation kit, where dozens of Ultra Durable Motherboards can be tested simultaneously. The Burn-in Chamber is set to 50°C to simulate the high temperature environments. Each GIGABYTE Ultra Durable motherboard model must pass all Stability Test loops, totaling 32 hours of non-stop burn-in, reboot, On/Off and resume testing.GIGABYTE's internal test procedure goes way beyond any normal usage scenario, where normal users only run full loading for a few hours. GIGABYTE uses customized programs to run stress tests, identify weaknesses and to improve the overall design and to assure long lifespan of GIGABYTE Ultra Durable Motherboards.

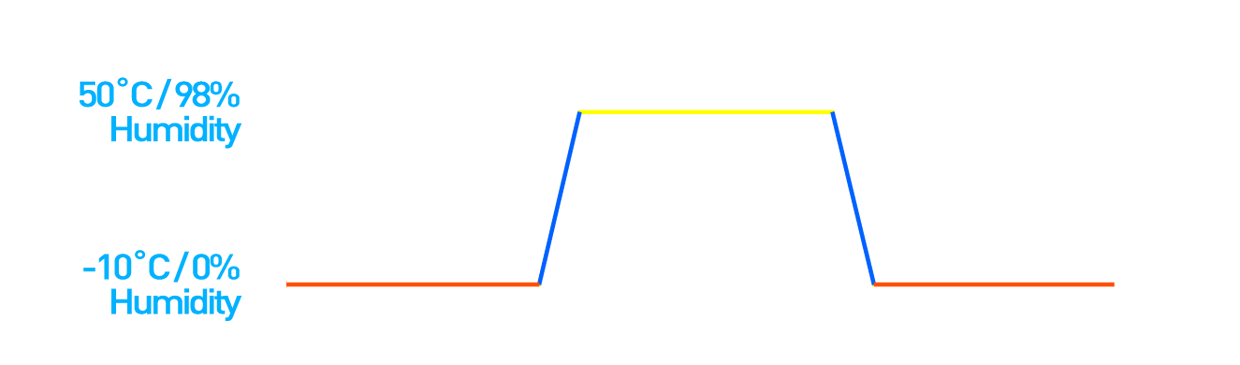

Critical Temperature Environment

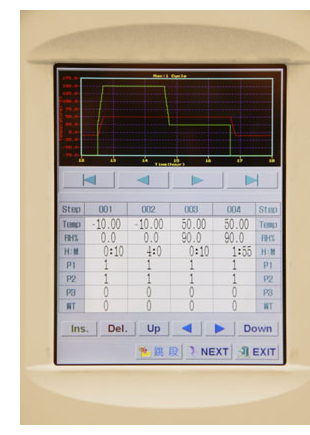

To Make sure GIGABYTE Ultra Durable Motherboards can work normally under the Critical Temperature Environment changes, each GIGABYTE Ultra Durable Motherboard must pass a Thermal Shock Process (High/Low Temperature Operational Test) in GIGABYTE’s R&D Laboratory.

For High Temperature Environments, the temperature will be set at 50°C with a humidity of up to 98%, for Low Temperature environments the temperature will be set at -10°C/0% humidity. Specialized test equipment is set to automatically run the motherboards for 4 hours at low temperature then slowly change to high temperatures for another 4 hours and repeating this test loop and cycle for 32 hours. Furthermore, during the test process motherboards are running non-stop testing a Reliability Test loop (3D Burn-In, On/Off, S3 Resume, Reboot).

GIGABYTE has a global logistic capacity and this test program assures Ultra Durable Motherboards can survive for long durations at sea in humid sea shipments to different critical environment countries with hot/humid weather such as India, or Cold/Dry weather in the Nordic region, and still function properly. If any components fail the test, our R&D can change the component or modify the design to solve any issues before starting to manufacture in mass quantities.

For High Temperature Environments, the temperature will be set at 50°C with a humidity of up to 98%, for Low Temperature environments the temperature will be set at -10°C/0% humidity. Specialized test equipment is set to automatically run the motherboards for 4 hours at low temperature then slowly change to high temperatures for another 4 hours and repeating this test loop and cycle for 32 hours. Furthermore, during the test process motherboards are running non-stop testing a Reliability Test loop (3D Burn-In, On/Off, S3 Resume, Reboot).

GIGABYTE has a global logistic capacity and this test program assures Ultra Durable Motherboards can survive for long durations at sea in humid sea shipments to different critical environment countries with hot/humid weather such as India, or Cold/Dry weather in the Nordic region, and still function properly. If any components fail the test, our R&D can change the component or modify the design to solve any issues before starting to manufacture in mass quantities.

Unstable Power Supply Environment

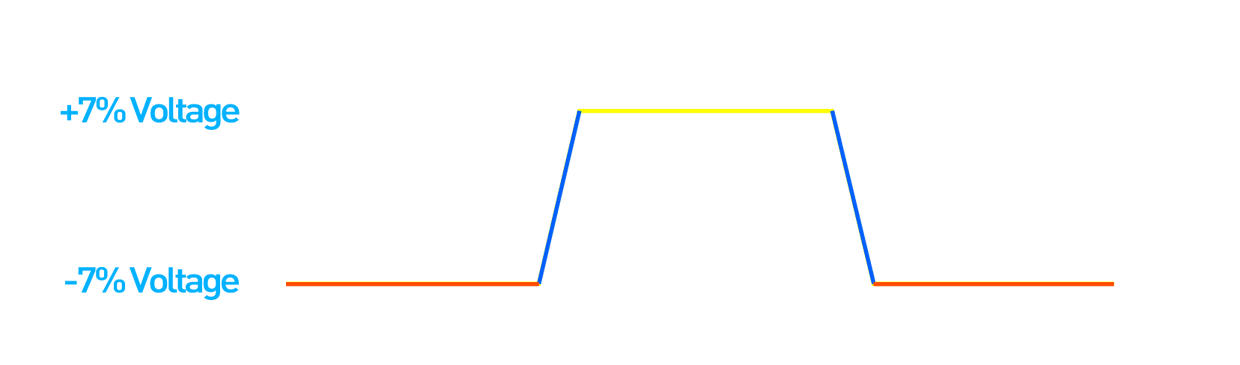

To make sure GIGABYTE Ultra Durable Motherboards can work normally under unstable power conditions, each GIGABYTE Ultra Durable Motherboard must pass Under/Over-Voltage Operation Testing in GIGABYTE’s R&D Laboratory.

A Customized power supply is prepared to provide an additional 7% voltage variance greater and less than the motherboard requires while the motherboards are running and tested under a Reliability Test Loop. This Loop consists of operating at 4 hours of a lack of 7% voltage and then slowly changing to an overvoltage scenario and running for another 4 hours. This test lasts for a total of 32 hours switching between the two scenarios. ccasionally, some parts or components on the motherboard will fail and in those scenarios GIGABYTE R&D will modify the original design or use more durable components so the motherboard can pass this test.

As the power infrastructure is not stable in some countries, this test confirms that GIGABYTE Ultra Durable Motherboards can work for long periods of time and maintain a good life cycle in these countries without optimum operating requirements.

A Customized power supply is prepared to provide an additional 7% voltage variance greater and less than the motherboard requires while the motherboards are running and tested under a Reliability Test Loop. This Loop consists of operating at 4 hours of a lack of 7% voltage and then slowly changing to an overvoltage scenario and running for another 4 hours. This test lasts for a total of 32 hours switching between the two scenarios. ccasionally, some parts or components on the motherboard will fail and in those scenarios GIGABYTE R&D will modify the original design or use more durable components so the motherboard can pass this test.

As the power infrastructure is not stable in some countries, this test confirms that GIGABYTE Ultra Durable Motherboards can work for long periods of time and maintain a good life cycle in these countries without optimum operating requirements.