Logistics Automation to Industrial World

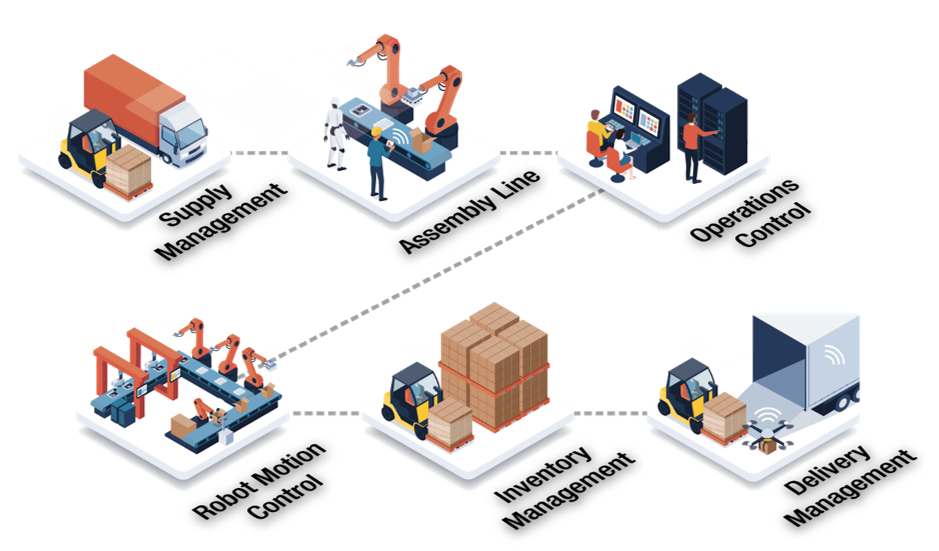

Industry 4.0 is a technical revolution to transform the whole manufacturing facilities into more automated and smarter operating systems through excellent internet connectivity. Thanks to IoT technology (IoT), it allows devices, objects or processes to be interacted and associate with each other to improve the results obtained, and also Artificial intelligence (AI) enables machines to process and learn from the information they receive and be able to act or response autonomously.

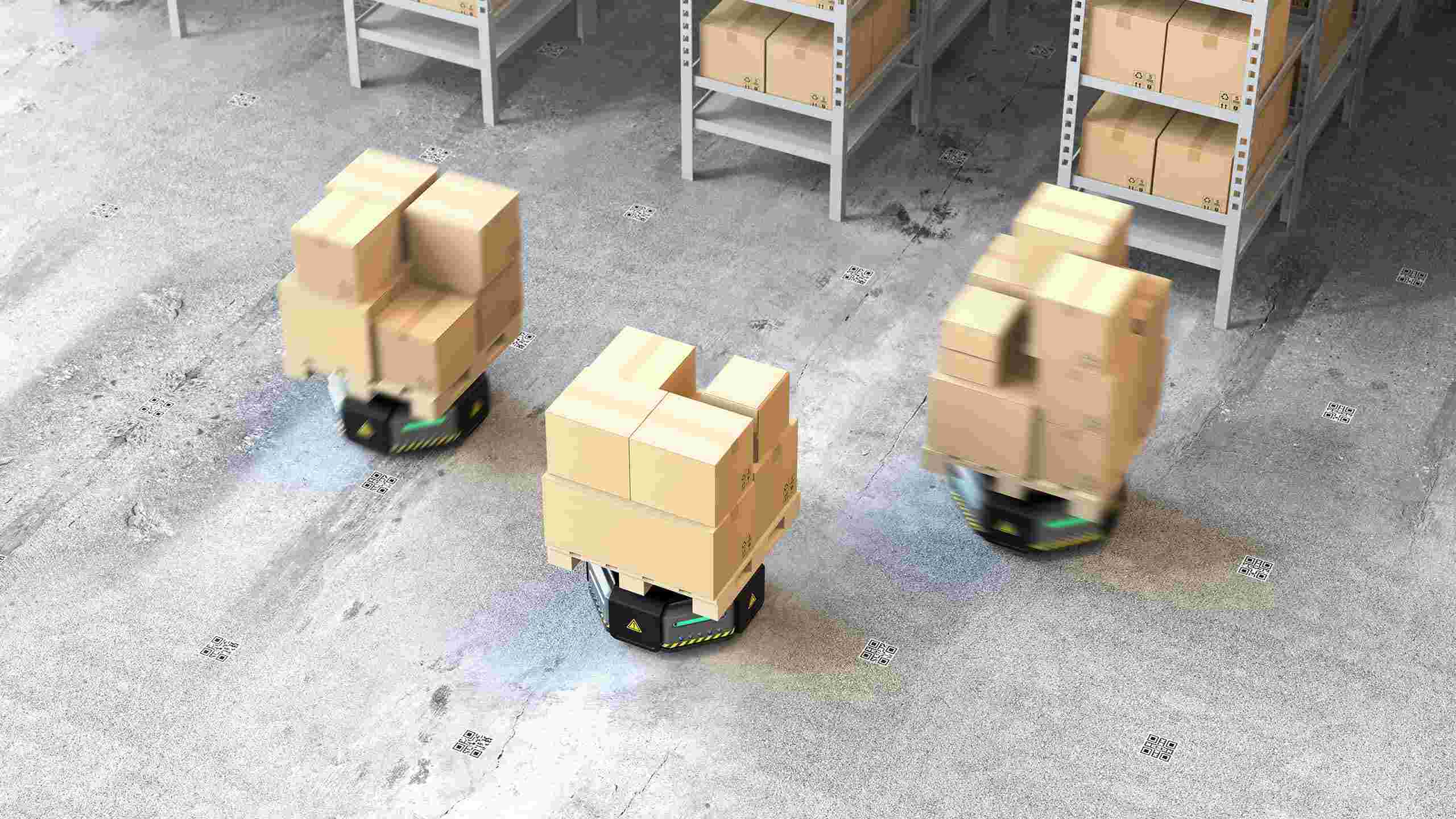

AGV / AMR play a major role in the whole smart manufacturing process. They represent the forefront technology in warehouse automation, from raw material loading and unloading and delivering throughout the areas of warehouse and assembly lines, making the production processes more productive and efficient with less human contact, also avoid any accidents during the processes. Especially, COVID-19 pandemic increases the demand of automated robotics in manufacturing filed in order to cope with manpower shortage at site.

GIGABYTE presents embedded solutions complying with industrial grade of anti-shock and anti-vibration and fan-less design for AGV / AMR applications. Numerous I/O interfaces allow to connect with cameras, sensors, and other devices as well as expansion slots for system upgrade and flexibility.

AGV / AMR play a major role in the whole smart manufacturing process. They represent the forefront technology in warehouse automation, from raw material loading and unloading and delivering throughout the areas of warehouse and assembly lines, making the production processes more productive and efficient with less human contact, also avoid any accidents during the processes. Especially, COVID-19 pandemic increases the demand of automated robotics in manufacturing filed in order to cope with manpower shortage at site.

GIGABYTE presents embedded solutions complying with industrial grade of anti-shock and anti-vibration and fan-less design for AGV / AMR applications. Numerous I/O interfaces allow to connect with cameras, sensors, and other devices as well as expansion slots for system upgrade and flexibility.

The Benefits of AGV & AMR

24-7 operation

Automated robots can operate 24-7 to increase productivity and efficiency, instead of the labor force's exhaustion from long-day physical works.

Increased Safety

It's programmed with safety in mind. With all the cameras, lasers, and sensors, it allow them to safely operate around personnel and infrastructures.

Cost Saving

By replacing human workers with AGV / AMR, labor costs and expenses can be reduced in the corporate operation.

High Computing Performance

With the latest Intel® 11th Gen core i processors, these solutions deliver intelligent computing capability for data transmitting and analysis.

Fan-less Design

Instead of traditional CPU fan, fan-less design protects the system from dusts and dirt, in order to extend product-life and for easy maintenance.

Longevity Support

The product design comply with industrial standard of anti-vibration and anti-shock, and the longevity support at least 5 years.