Guaranteeing Safety and Operational Efficiency

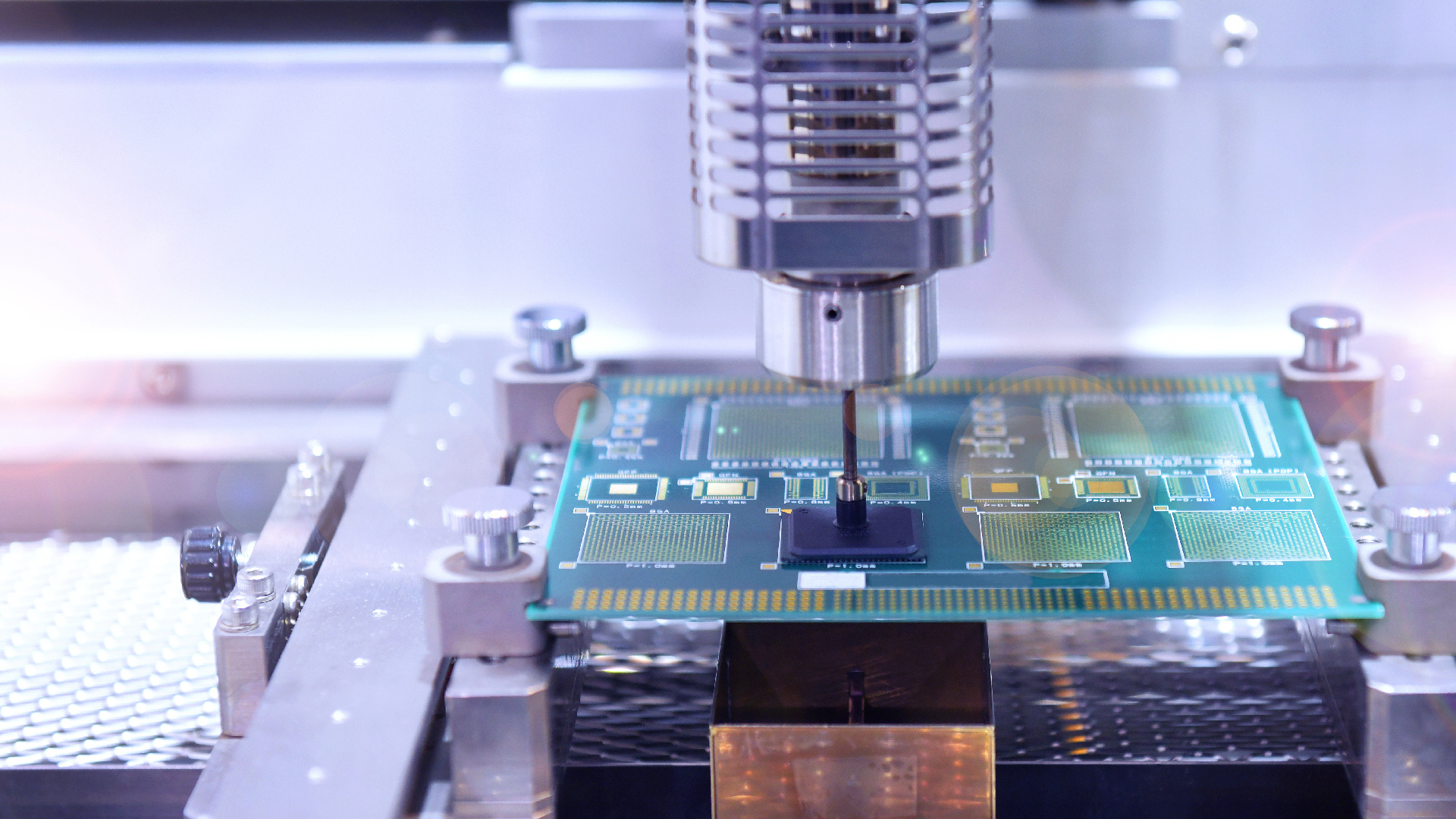

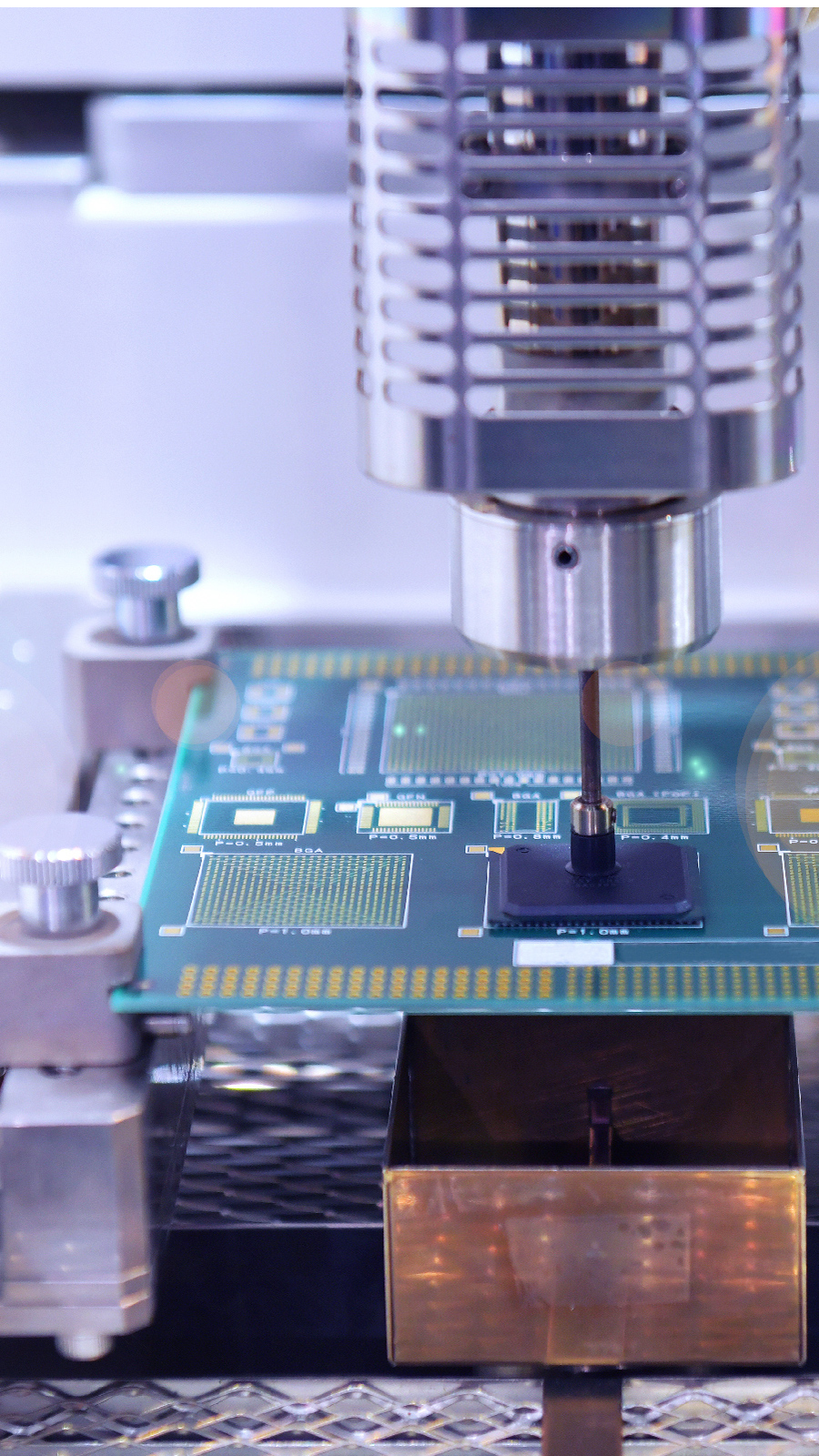

ESD testing assisted by a facial recognition system is the best way to optimize the ESD safety check process in an industrial environment. ESD testing is widely used to ensure that an employee who enters the working area does not have a build-up of static electricity that might cause serious damage to the assembly line. By integrating artificial intelligent facial recognition with the ESD testing process, records of ESD testing automatically link identification records to each time the test was conducted. If an employee does not pass ESD testing, they cannot enter the work area. Real-time records and statistical reporting will also be available from a management dashboard. A manager can search and analyze data via the MIS system. Neo ESD Inspection Powered by Facial Recognition is designed to cover a diverse range of industrial environments. The inspection process and API can also be customized.

Creating Safer Workplaces

How Does It Works

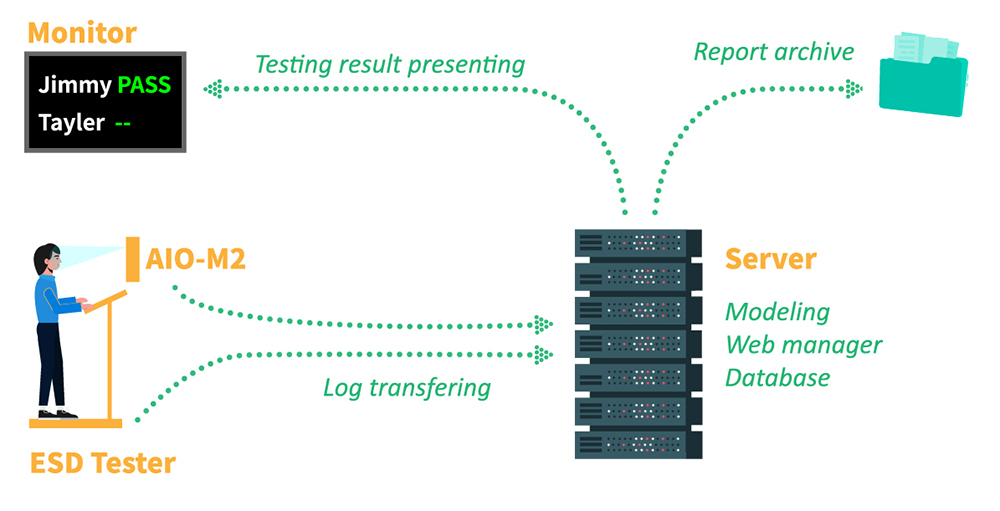

We assist factories that need to control static electricity to upgrade the level of safety control in their operating area. The ESD test results will be archived according to the facial recognition result, and each individual will have an automatic personal ESD test result. To secure the assembly line, a person who does not pass the ESD tester will not able to enter the operating area. The test result can be displayed on a monitor in real time and archived to the internal system upon request.

System Architecture

Case Study

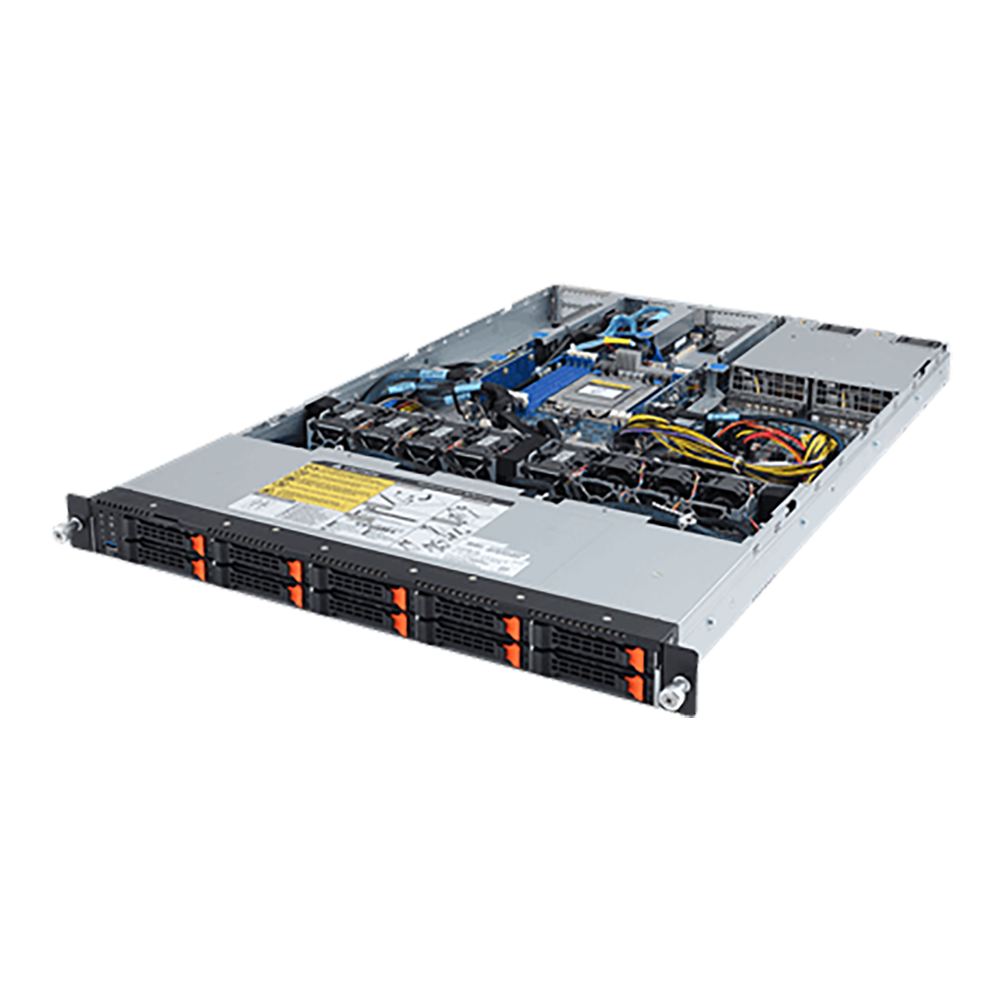

Applying in GIGABYTE - Nan-Ping Manufacturing plant, Taiwan, to serve up to 1500 staff members. Access will be granted after the employees pass the detection of both ESD tester and Facial Recognition system. The detection results of ESD tester will be shown at the upper left corner of the monitor accordingly.

Benefit

Optimized Procedures

Assembly line safety is secured when access control depends on the ESD detection result.

Organized Inspection Database

Facial recognition records and ESD test results can be complied with in a secure inspection database.

Reduced Administrative Workload

Role-based access control allows for flexible authorization capabilities for factories with multiple shifts and multiple global locations.