Two-Phase Immersion Cooling with LiquidStack

GIGABYTE has joined forces with LiquidStack and 3M to offer a Two-Phase Immersion Cooling solution, allowing customers to drastically reduce their data center energy consumption and improve PUE, radically reducing operating costs and environmental impact.

Download White Paper

Introduction

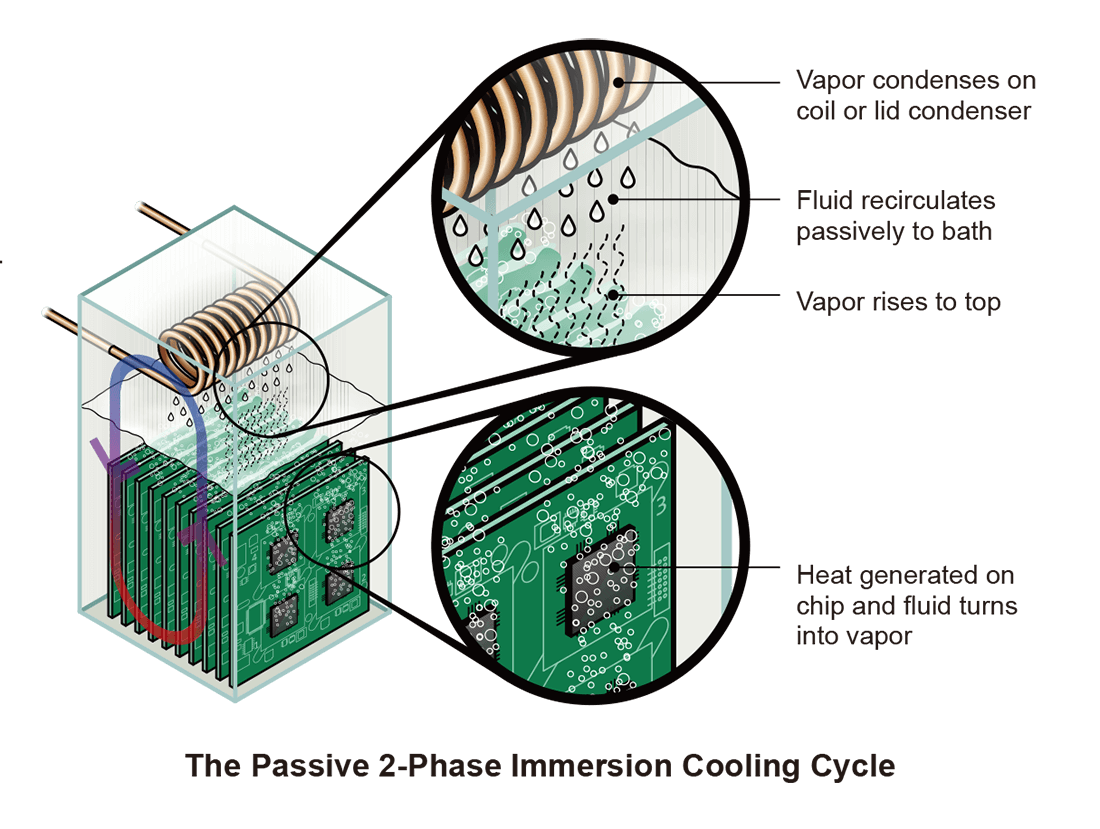

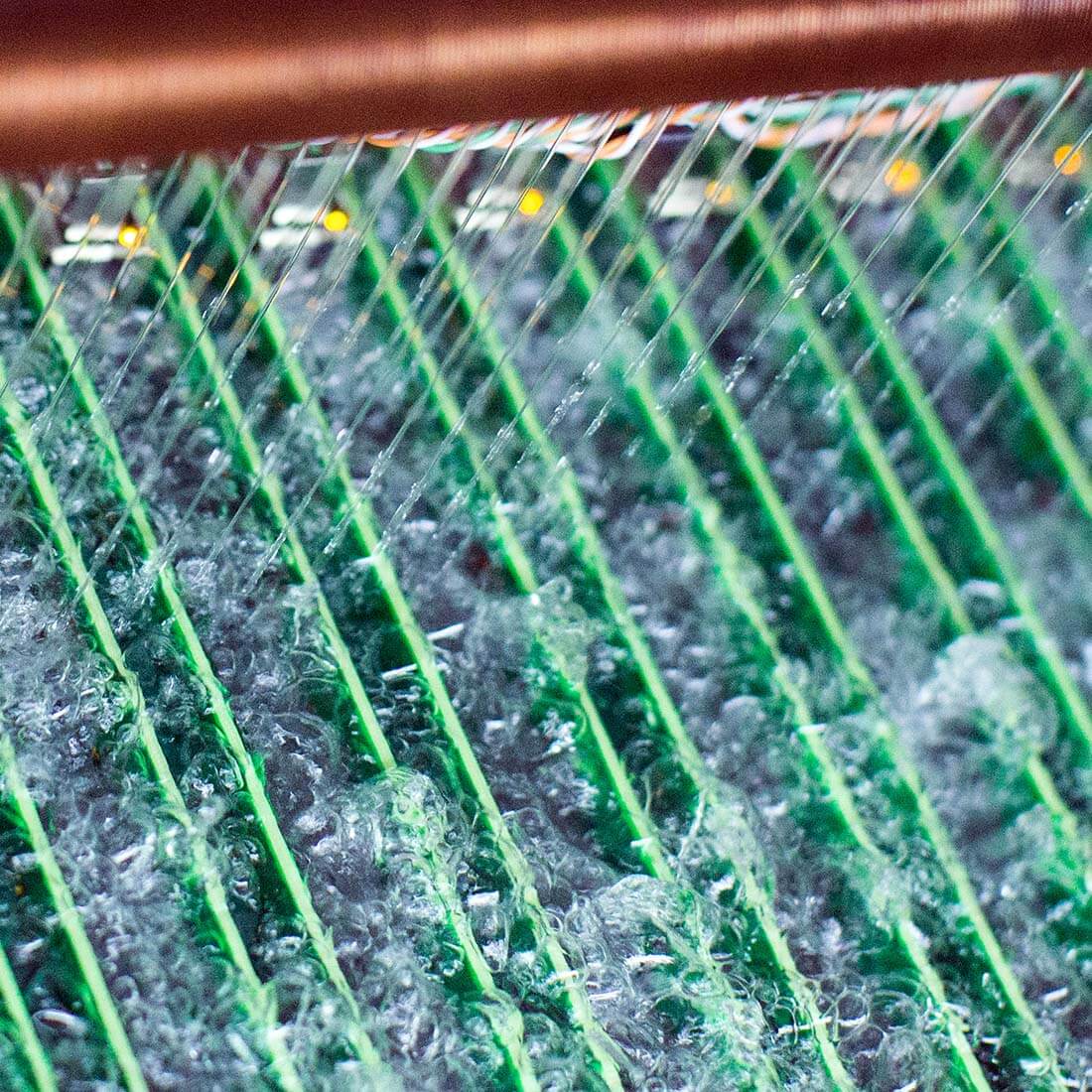

Two-phase Immersion cooling is a new type of cooling technology for data centers. In a two-phase immersion cooled system, electronic components are submerged into a bath of dielectric heat transfer liquid, which is a much better heat conductor than air, water or oil. With a low boiling point at 50°C, the fluid boils on the surface of heat generating components, and rising vapor passively takes care of heat transfer.

In contrast to submersion oil cooling, two-phase immersion cooling liquids are clean, environmentally friendly and non-flammable. No pumps and jets are required to keep hardware cool. Circulation happens passively by the natural process of evaporation and without spending any extra energy. It is this simplicity that eliminates conventional cooling hardware and results in better cooling efficiency. Compared to traditional air, water or oil cooling, this passive process results in the use of much less energy.

In contrast to submersion oil cooling, two-phase immersion cooling liquids are clean, environmentally friendly and non-flammable. No pumps and jets are required to keep hardware cool. Circulation happens passively by the natural process of evaporation and without spending any extra energy. It is this simplicity that eliminates conventional cooling hardware and results in better cooling efficiency. Compared to traditional air, water or oil cooling, this passive process results in the use of much less energy.

Usage Scenarios

5G, Edge Computing

The era of 5G will require telcos to invest more in edge computing to reduce data transfer latency. Edge data centers are often located in urban areas and have a restricted amount of space. Two-phase immersion cooling allows for a much greater density of processing capabilities in a restricted space, making it ideal for an edge computing deployment.

AI, Machine Learning

Training algorithms for artificially intelligent applications requires a large amount of parallel processing power, delivered by dense GPU deployments. A large number of high powered GPUs produce a lot of heat, requiring high electricity bills for air cooling and air conditioning. Two-phase immersion cooling is a much more cost efficient and environmentally friendly solution.

Blockchain, Crypto

Blockchain and crypto rely on the verification of each endpoint in a peer-to-peer network to protect information. As more and more machines are connected to the network, authentication becomes frequent and mathematical calculations getting difficult, causing the computer to generate higher heat. Two-phase immersion cooling is a cost effective and environmentally friendly solution.

High Frequency Trading

High-frequency trading requires high-performance computing systems that can provide ultra-low latency to strive for timeliness. The transaction time difference of milliseconds may be profits and losses of millions dollars. Two-phase immersion cooling can achieve higher overclocking possibilities for these extreme applications.

Advantages of Two-Phase Immersion Cooling

Higher Efficiency and Energy Savings

>90% efficiency advantage in the data centers compares to air cooling - including server power consumption and air conditioning costs.

Improved Reliability

Components are not subject to temperature variations, reducing failure potential & no cooling fans required, eliminating degradation from vibration.

Higher Computing Density

No need for heat sinks and cooling fans means computing parts can be placed closer, which can increase computing power by 10 times in the same space.

Lower Maintenance Requirement

Passive cooling system means no unnecessary parts to build or service, useful especially for remote locations such as edge computing stations.

How Does Two-Phase Immersion Cooling Work?

Servers or other IT components are submerged in a thermally conductive dielectric liquid or coolant. Heat is removed from the system by circulating the liquid into direct contact with hot components, whereby the liquid undergoes a low-temperature evaporation process to cool the hot components and transfer the heat out of the liquid. The gas is cooled again by a heat exchanging method such as a condenser coil to allow return flow into the larger liquid volume.

Although two-phase immersion cooling has several different variations, LiquidStack technology uses an "open bath" system, using a tank which contains a larger body of dielectric liquid where multiple servers are immersed into the bath, sharing the same liquid. The open bath system is fully sealed and can be opened from the top to service IT equipment.

Immersion Cooling Solution Partners

Immersion Cooling Infrastructure – LiquidStack

Headquartered in Hong Kong, LiquidStack is a pioneer in building the most efficient cooling solutions for high density electronics, and the first to successfully implement immersion cooling technology in commercial operations since 2012. LiquidStack have also created the world's largest immersion cooling data centers with 40MW and 120MW IT load capacities. They are an official technology partner of 3M and GIGABYTE for immersion cooling fluids, and have won the both the Data Center Dynamics "Future Thinking and Design Concepts” Award and the "Best Green ICT" Award for the most energy efficient Data center (PUE 1.01).

Headquartered in Hong Kong, LiquidStack is a pioneer in building the most efficient cooling solutions for high density electronics, and the first to successfully implement immersion cooling technology in commercial operations since 2012. LiquidStack have also created the world's largest immersion cooling data centers with 40MW and 120MW IT load capacities. They are an official technology partner of 3M and GIGABYTE for immersion cooling fluids, and have won the both the Data Center Dynamics "Future Thinking and Design Concepts” Award and the "Best Green ICT" Award for the most energy efficient Data center (PUE 1.01).

Immersion Cooling Fluid – 3M™ Fluorinert™ Electronic Liquids

3M has a long-held leadership position in immersion cooling fluids, beginning in the 1950s when 3M introduced its first dielectric fluorochemical heat transfer fluids for direct contact cooling for military avionics. Over the past five years, 3M engineered fluids have been used in server cooling and have been recognized by the industry for best in class energy efficiency.

GIGABYTE uses and recommends 3M™ Fluorinert™ Electronic Liquids fluids for a two-phase immersion cooling system. Fluorinert fluids are clear, colorless, non-conductive, non-flammable, residue free, thermally and chemically stable liquids. Fluorinert fluids have an extremely narrow boiling range, so the composition will not deviate with time, insuring consistent transport properties.

3M™ Fluorinert™ Electronic Liquids have among the highest dielectric strength and electrical resistivity of all organic fluids, much better in fact than air. And unlike hydrocarbon liquids such as mineral oil, 3M™ Fluorinert™ Electronic Liquids are completely fluorinated. This means they have little or no solvency for hydrocarbons. Components taken out of 3M™ Fluorinert™ Electronic Liquids also dry out easily, and won't be wet, sticky or oily. There is no need to prepare rubber mats, tissues or other materials when taking the servers out of the liquid for maintenance.

3M™ Fluorinert™ Electronic Liquids-Product Links

https://www.3m.com/3M/en_US/p/d/b10144228/

3M has a long-held leadership position in immersion cooling fluids, beginning in the 1950s when 3M introduced its first dielectric fluorochemical heat transfer fluids for direct contact cooling for military avionics. Over the past five years, 3M engineered fluids have been used in server cooling and have been recognized by the industry for best in class energy efficiency.

GIGABYTE uses and recommends 3M™ Fluorinert™ Electronic Liquids fluids for a two-phase immersion cooling system. Fluorinert fluids are clear, colorless, non-conductive, non-flammable, residue free, thermally and chemically stable liquids. Fluorinert fluids have an extremely narrow boiling range, so the composition will not deviate with time, insuring consistent transport properties.

3M™ Fluorinert™ Electronic Liquids have among the highest dielectric strength and electrical resistivity of all organic fluids, much better in fact than air. And unlike hydrocarbon liquids such as mineral oil, 3M™ Fluorinert™ Electronic Liquids are completely fluorinated. This means they have little or no solvency for hydrocarbons. Components taken out of 3M™ Fluorinert™ Electronic Liquids also dry out easily, and won't be wet, sticky or oily. There is no need to prepare rubber mats, tissues or other materials when taking the servers out of the liquid for maintenance.

3M™ Fluorinert™ Electronic Liquids-Product Links

https://www.3m.com/3M/en_US/p/d/b10144228/

Immersion Cooling Servers with GIGABYTE

GIGABYTE is an industry leader in server systems for High Performance Computing, an application that is particularly suited to immersion cooling due to the high power consumption and heat generated by high performance processors. GIGABYTE can easily modify our standard server products to make them fully compatible with an immersion cooling system.

GIGABYTE Server Lineup & Immersion Cooling POC Unit Compatibility

Immersion Cooling POC Unit

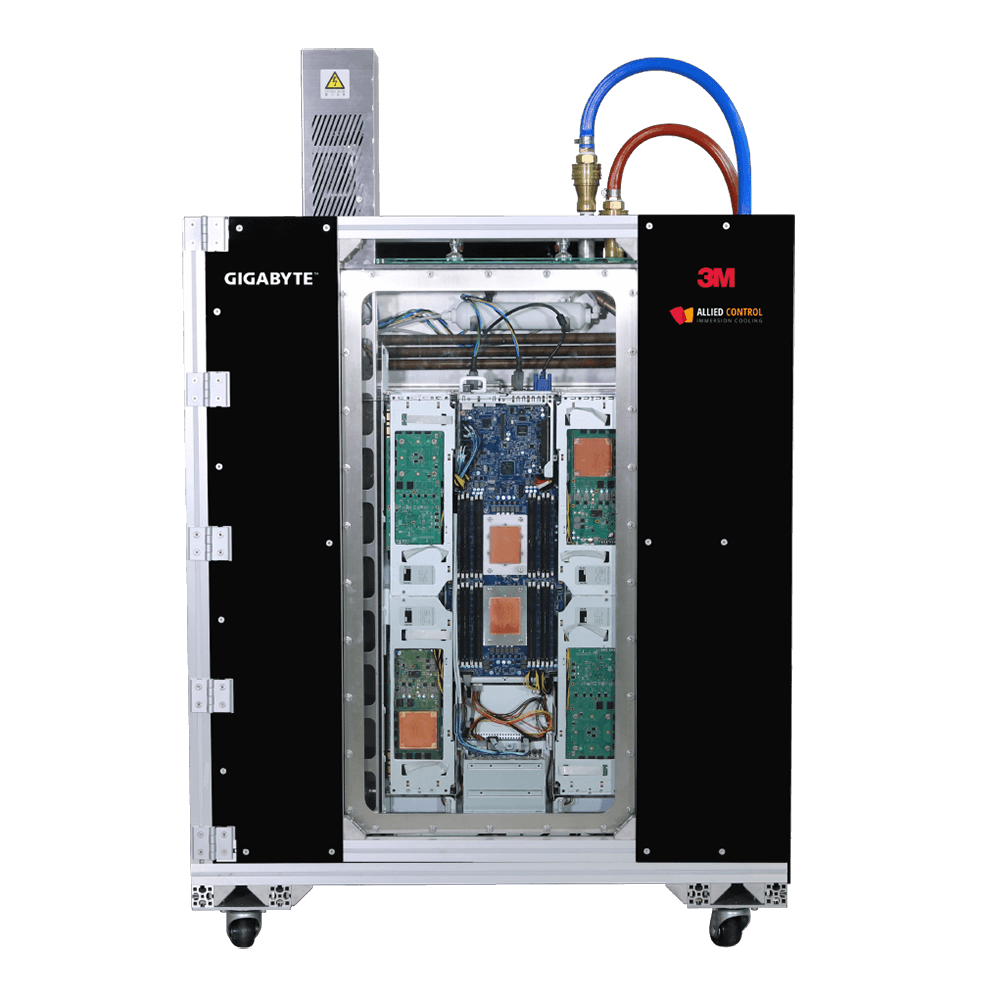

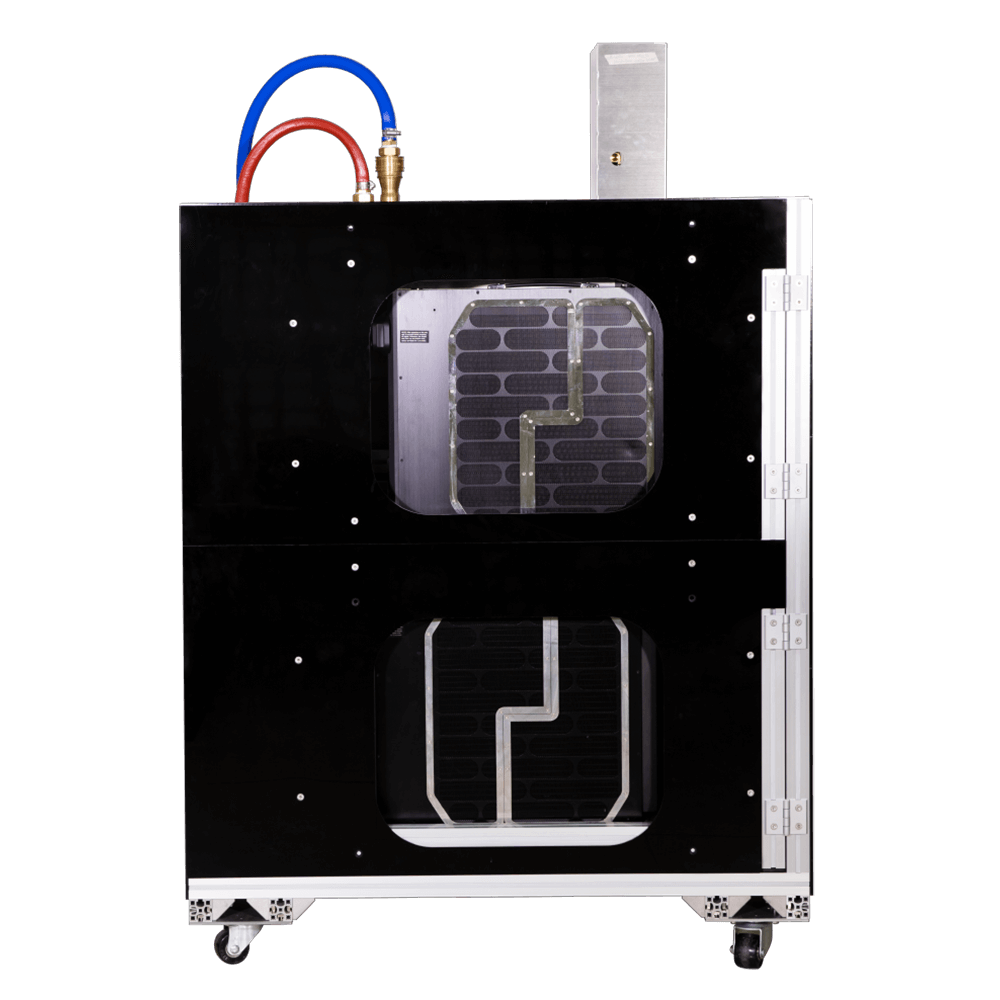

GIGABYTE has also designed an Immersion Cooling POC (Proof of Concept) Unit for testing and validation. This unit is fully compatible with our 2U form factor servers. The unit can also be modified on request to suit our other form factor (1U or 4U) models. Please download our brochure for detailed specifications of the POC unit.

1/4

Front View

2/4

Inner View

3/4

Top View

4/4

Rear View

Related Technologies

What is a data center?

A data center is a facility that an organization uses for housing their IT equipment, including servers, storage, networking devices (such as switches, routers and firewalls), as well as the racks and cabling needed to organize and connect this equipment. This equipment also requires infrastructure to support it such as power distribution systems (including backup generators and uninterruptible power supplies) and ventilation and cooling systems (such as air conditioning systems or liquid cooling systems). A data center can range in size from a single room to a massive multi-warehouse complex.

In 2005, the American National Standards Institute (ANSI) and the Telecommunications Industry Association (TIA) published standard ANSI/TIA-942, "Telecommunications Infrastructure Standard for Data Centers", which defines four tiers of data centers by various levels of reliability or resilience. For example, a Tier 1 data center is little more than a server room, while a Tier 4 data center offers redundant subsystems and high security.Learn more:

《How to Build Your Data Center with GIGABYTE? A Free Downloadable Tech Guide》

What is it? PUE (Power Usage Effectiveness) is the ratio of the total amount of power used by a data center compared to the power that's actually delivered to the computing equipment. An ideal PUE ratio would be 1.0: 100% of the power delivered to the data center is used for computing. However, data centers require cooling systems, lighting, and other equipment that will also consume some of this power. As such, the PUE for a conventional data center will always be greater than 1.0.

Immersion cooling is a type of liquid cooling method where the servers are directly immersed inside a bath of non-conductive, dielectric liquid. Heat given off by the servers' components is transferred to the surrounding liquid. Because of the temperature gradient in the liquid, the heated liquid that is less dense rises to the top. As this occurs, the liquid is removed from the top of the tank and replaced with cooler liquid from the bottom. This heat transfer process is called natural convection. Therefore, the immersion cooling system does not require additional active cooling components, such as fans, and so it can go a long way toward improving your data center's energy efficiency.There are two types of immersion cooling, which work in slightly different ways.●Single-Phase Immersion CoolingIn this process, the coolant will not change its state by evaporating, it always remains a liquid. The warm coolant in the tank is pumped out by the coolant distribution unit (CDU) and the heat is transferred to a heat exchanger, which is a secondary cooling circuit that transfers the heat to facility water or outside air. ●Two-Phase Immersion CoolingThe cooling method in two-phase is similar to single-phase in that the coolant absorbs the heat from the servers or IT components; however, in two-phase immersion cooling, the liquid changes state. As the coolant reaches its ultra-low boiling point, the vapor bubbles rise to the top and enter a gaseous state. After evaporating, the vapor comes in contact with a condenser that returns it back to its liquid state. The fluids flow back into the bath to renew the cycle.

Resources

Bring Your Ideas Faster to Fruition

Email Sales